thickness 0.19 in.measure|stainless steel thickness chart : exporter sheet metal gauge chart, sheet metal gauge size, sheet metal thickness, sheet metal gauge Created Date: 2/15/2011 3:35:40 PM . webDismef Distribuidora de Materiais Elétricos Hidráulicos e Fe. Endereço: Ralpho Leite Barros, R, nº 165 Jd Trevo - Campinas - SP. Cep: 13040-020. Ramo: Materiais Elétricos - Lojas

{plog:ftitle_list}

De acordo com as pesquisas que encontrei, os melhores horários para jogar Fortune Rabbit são: Manhã: entre 9h e 11h. Tarde: entre 15h e 17h. Noite: entre 21h e 23h. .

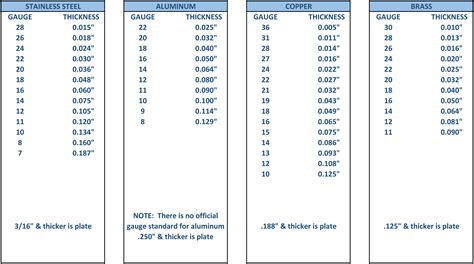

Sheet metal gauge is a fundamental measurement in metalworking that denotes the thickness of sheet metal. Originating from the Browne & Sharpe system in North America, gauge is a standardized unit used .

The standard thickness for sheet metals will vary depending on the type of metal. A sheet metal gauge chart uses the thickness and weight per area of different metals to determine standardised thicknesses or ‘gauges’. .sheet metal gauge chart, sheet metal gauge size, sheet metal thickness, sheet metal gauge Created Date: 2/15/2011 3:35:40 PM .Measure the sheet metal thickness. Compare the sheet metal thickness with the sheet metal gauge chart against the specified material. To sum up, Sheet metal thickness charts convert .The following sheet metal gauge size reference chart gives the weight and thickness of sheet metal given as a "gauge" (sometimes spelled gage) and indicates the standard thickness of .

These charts provide thickness by gauge size for the following materials: – Standard Steel. – Galvanized Steel. – Stainless Steel. – Aluminum. – Zinc. – Birmingham Scale. Each was determined by a standard established by .

The standard or metric equivalent of a gauge value depends on the metal. For example, 18-gauge sheet metal would be 0.040 inches thick if made from aluminum and .Use our handy chart to convert standard gauge numbers in decimals of an inch for sheet steel, aluminum and stainless steel.

gas springs 12 inches compressed

standard thickness of sheet metal

Thickness of material can be a rather abstract concept when you’re first getting started. So, we’ve put together a list of comparisons to help you get a sense for the thickness .The higher the gauge number, the lower will be the sheet thickness. For example, a 16 gauge CRCA sheet metal measures 1.5 mm thickness. Whereas, a 16 gauge aluminum sheet measures 1.3 mm thickness. This article can help engineers in sheet gauge number to mm or inch conversion. Sheet Metal gauges are not standardized. BACKGROUND: B-mode ultrasound can be used to measure diaphragm thickness at the zone of apposition. We believe it is necessary to develop normal values for diaphragm thickness at rest in a large group of . The phase-sensitive eddy current method is well suited for copper thickness measurement in PC board boreholes and surface copper thickness measurement on PC boards. It is also suited for measuring nonferrous metal coatings, such as copper, aluminum or brass over a nonferrous or electrically nonconductive substrate. The unit shown in Figure 7 .

Are you looking for a way to convert 0.19 inches to mm? To answer the question first, it is 4.826 mm. But what is the conversion factor? That is what this page is about, as we will show you the many different ways to convert 0.19 inches to their mm equivalent. The issues that determine what method is best for a given coating measurement include the type of coating, the substrate material, the thickness range of the coating, the size and shape of the part and the cost of the equipment. Commonly used measuring techniques for cured organic films include nondestructive dry film methods such as magnetic, eddy current, .

If you know the thickness, you can use it to figure out other useful things such as weight. These thicknesses vary based on what the material is. In general, as the gauge number increases, the thickness decreases. These charts provide thickness by gauge size for the following materials: – Standard Steel – Galvanized Steel – Stainless SteelThe thickness, in mm, of metal washers is measured on samples of size 5. The following table presents the means, ranges, and standard deviations for 20 consecutive samples. Sample X R S Sample R S 1 2.49 0.12 0.07 11 2.54 0.19 0.07 2 2.45 0.17 0.06 12 2.45 0.09 0.04 3 2.51 0.13 0.06 13 2.54 0.21 0.07 4 2.53 0.25 0.09 14 2.55 0.10 0.05 5 2.49 0. .

sheet metal gauge chart, sheet metal gauge size, sheet metal thickness, sheet metal gauge Created Date: 2/15/2011 3:35:40 PM . VIDEO ANSWER: x B D is a random variable that represents the recording thickness quoting. Each value is distributed uniformly. Uh 0.05. There was little. Little.118 There is a little point. There are five values in this picture. . Thickness measurement: In the coating process, the nearest hundredth of a millimeter is made. The thickness .

VIDEO ANSWER: x B D. Random variable that represents, that represents the recording thickness quoting take this given X. Is uniformly distributed among the values. Uh 0.15. Little .16. Little .118. Little Point 19. As there are five values among . Thickness measurement: In the coating process, the nearest hundredth of a millimeter is made. .Objectives: Measurement of endometrial thickness is an important tool in the assessment of women with postmenopausal bleeding, but the role of endometrial thickness measurement by ultrasound in asymptomatic women is unclear. The aims of this study were to determine: (1) the normal endometrial thickness measured by ultrasonography, (2) the prevalence of serious . The aims of this study were to determine: (1) the normal endometrial thickness measured by ultrasonography, (2) the prevalence of serious endometrial pathology and (3) the sensitivity and specificity of endometrial thickness measurement by transvaginal ultrasonography (TVS) for diagnosing premalignant and malignant endometrial disease in .

Cross Sectioning Coating thickness measurement by cross sectioning of the test piece is an optical measurement of a coating under a microscope. The first step in cross sectioning is to overplate the specimen with 0.5 to 1 mil of a different metal. After overplating, the sample is cut and potted in another material such as an epoxy resin. .The thickness measurements are uniformly distributed with values 0.15,0.16 , During the luteal or secretory phase, endometrial thickness grows to an average of 12 to 13 mm, which lasts from days 14 to 28. The endometrial thickness is typically less than five millimeters in postmenopausal women who are not on hormone therapy. However, the endometrial thickness in women who are on hormone therapy can reach up to 15 mm..17,0.18,$ and The thickness measurements are uniformly distributed with values 0.15 , An inch is a unit of length or distance in a number of systems of measurement, including in the US Customary Units and British Imperial Units. One inch is defined as 1⁄12 of a foot and is therefore 1⁄36 of a yard. According to the modern definition, one inch is equal to 25.4 mm exactly..16,0.17,0.18,$ and Measuring Cover Glass Thickness. It is simple to measure coverslip thickness with a digital micrometer. I use a Neoteck digital micrometer with a resolution of 0.001 mm (cost online). It is impractical to measure coverglass thickness routinely unless one is performing high resolution measurements or trying to detect single molecules..19 .$ Determine the mean and variance of the coating thickness for this process. Thickness measurements of a coating process are made to the nearest hundredth of a millimeter..19 .$ Determine the mean and variance of the coating thickness for this process. Thickness measurements of a coating process are made to the nearest hundredth of a millimeter.Alloy steel sheets and plates are solid and flat with no surface texture. Plates have a thickness of ¼” (6mm) or more, while sheets are less than ¼” (6mm) thick. They are available in different material grades that provide distinct levels of strength .Thickness: 0.19 "Stock Available in: all 6 locations Available Sizes for this Product. Material Meets These Standard(s): ASTM-B209, AMS-4027 Read More Specifications See Product Guide. 2 Select length and width below .

Thickness dramatically affects the functionality of coatings. Accordingly, the techniques in use to determine the thickness are of utmost importance for coatings research and technology. In this review, we analyse some of the most appropriate methods for determining the thickness of metallic coatings. In doing so, we classify the techniques into two categories: (i) . Actual Thickness: This is the precise, measured thickness of the stainless steel material, usually determined using high-precision measuring tools. Actual thickness is generally reported to two decimal places (e.g., 0.85mm, 1.91mm, 2.75mm, 3.80mm) for enhanced accuracy in engineering and fabrication processes. The discrepancy between nominal . Figure 4: Schematic diagram of a probe utilising the magnetic induction method to measure the thickness of a coating on a ferromagnetic substrate. The thickness of the coating dictates the current and subsequent magnetic field generated. The change in current/ magnetic field is measured by a secondary coil around the probe tip and converts the .

Understanding and measuring the thickness of plastic films and sheets is crucial for quality control, product development, and engineering purposes. In this comprehensive guide, we will explore the intricate world of plastic gauge thickness, providing a thorough Plastic Gauge Thickness Chart, explanations on conversion methods, and insights . Thickness measurement results presented in Table 4, Table 5, Table 6, and 7 show that of 126 measurements (for both aluminum and copper materials and 2 energy levels 511 keV, 661.7 keV) only 18 of 126 cases (14.3%) have a D G value of greater than 1, with the largest value RG of being 1.94 (see Fig. 6). In addition, 117 of 126 (92.9%) cases .An inch is a unit of length or distance in a number of systems of measurement, including in the US Customary Units and British Imperial Units. One inch is defined as 1⁄12 of a foot and is therefore 1⁄36 of a yard. According to the modern definition, one inch is equal to 25.4 mm exactly.

An ultrasonic thickness gauge’s working principle is that the ultrasonic waves are used in measuring the thickness without damaging the material. Ultrasonic thickness measurement (UTM) can determine the thickness of a solid material. Using an ultrasonic thickness gauge on ships and offshore has made working with hazardous materials safer and reliable.

gas springs compressed size 7inch

standard gauge to thickness chart

gas springs compressed size 7inch 100lbs lift

stainless steel thickness chart

4:16. 2 novinha safada rebolando e mostrando a raba na live. 3 years. 2:25. Mc Dosura deixando a toalha cair. 2 years. 9:58. Compilation das safadas mostrando a bct e a raba e dancando em live. 3 years.

thickness 0.19 in.measure|stainless steel thickness chart